Real estate developers

Dome Construction takes Lean approach to establish a culture of continuous improvement

Summary

- Dome Construction sought our help to ease employee burnout by adopting a Lean approach that prioritized respecting people and creating customer value.

- Our team started with a deep dive into Dome’s business, goals, internal processes, leadership approach, and collaboration style, then customized a Lean plan to create a culture focused on Dome’s most valuable resource — its people.

- Through this approach, we improved several internal processes to use resources better, and we helped teams become more efficient.

- Ultimately, the changes we created helped Dome rank on the San Francisco Business Times list of best places to work.

Client challenge

Mark Bley, the now-retired CEO of Dome Construction, had growing concerns about his staff members’ happiness; they were working long hours to deliver projects and were burning out. He knew that employee satisfaction was crucial to retaining and recruiting top talent in the San Francisco Bay Area. He also knew that the organization could better deliver on its core values — “Value our People,” “Seek to Understand,” and “Do it Right,” — which were fundamental to staff satisfaction. Bley was drawn to Lean to address these challenges because its central tenets aligned with Dome’s core values. But he knew it would be difficult for the organization to successfully implement lasting change without the right approach.

After a few failed attempts, Dome Construction turned to Haley & Aldrich because our Lean advisors first seek to deeply understand an organization, its people, its culture, and its challenges. This approach would allow us to guide Dome’s team members toward sustainable change.

Our approach

Haley & Aldrich’s Lean practitioners knew that an off-the-shelf Lean approach would not help Dome leaders transform the organization’s culture to better align with and enhance its specific values. That’s why we started by understanding Dome’s business, goals, internal processes, leadership approach, and how people work together. This knowledge allowed us to partner with Dome through a Lean journey with a tailored, strategic roadmap.

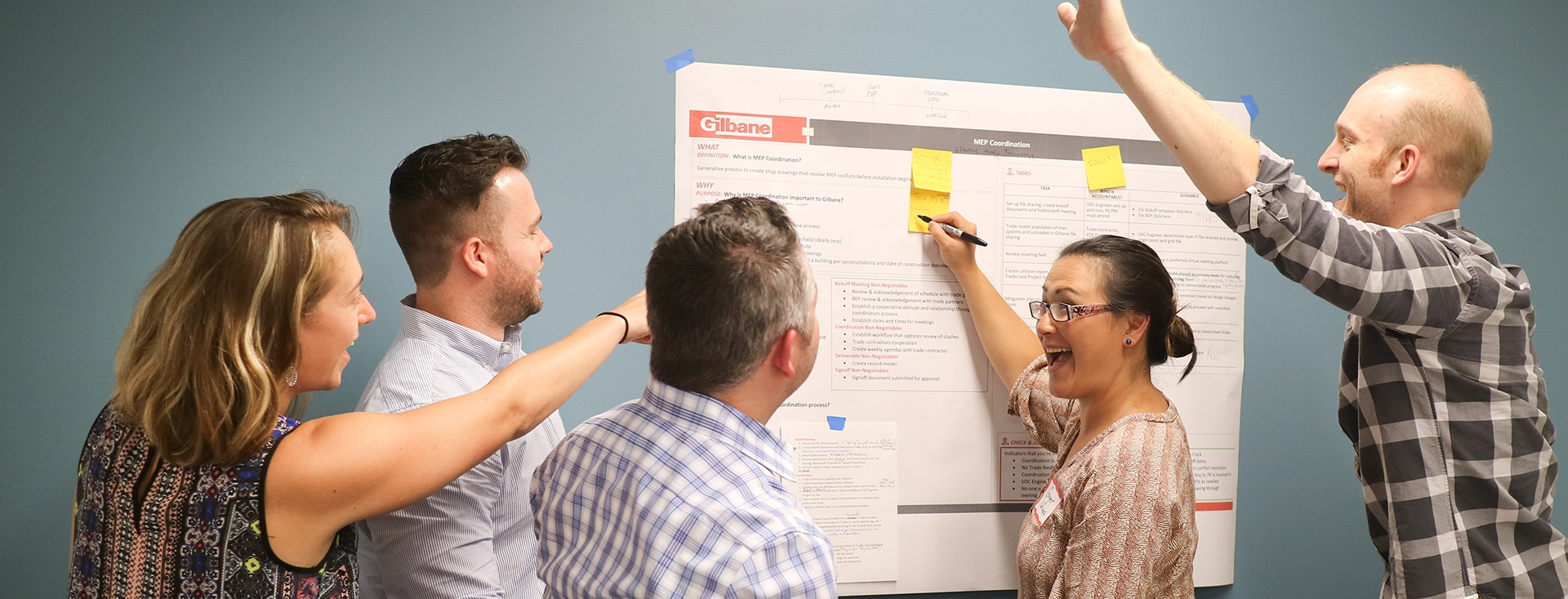

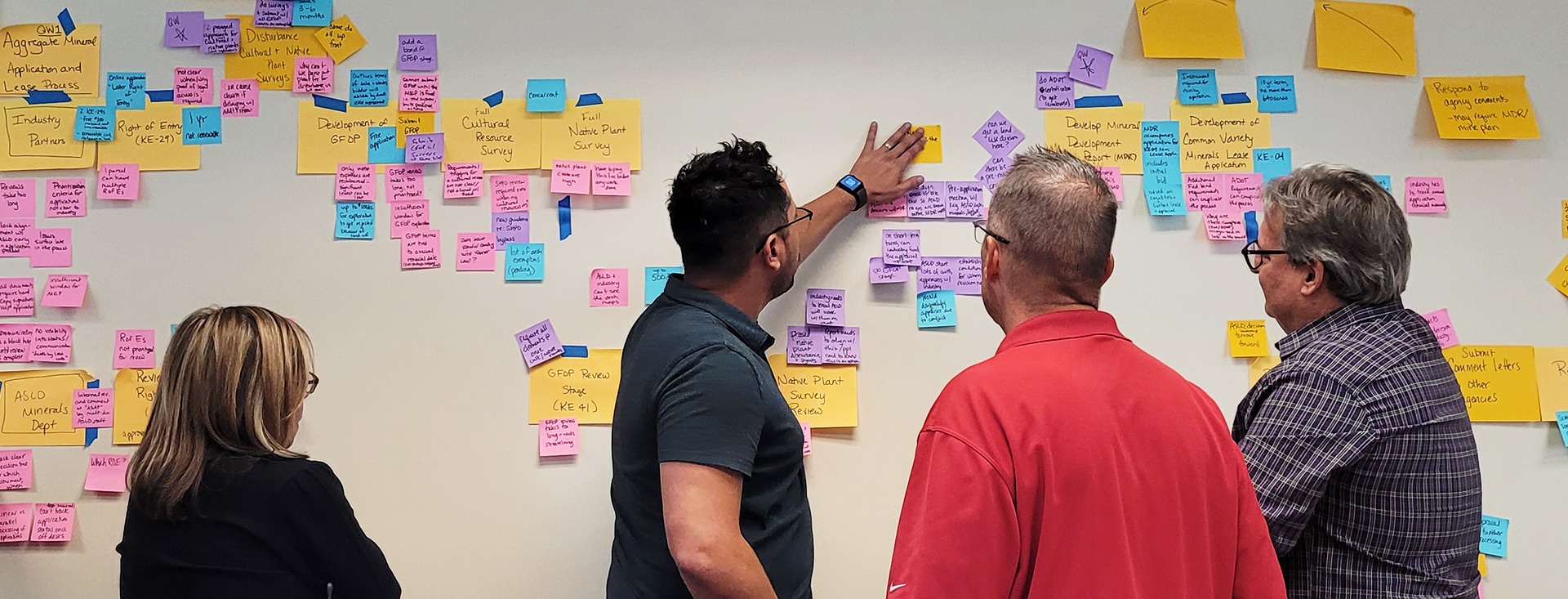

We brought together a cross-section of people across departments and seniority levels to develop a common understanding of the current state, identify areas that were consuming significant time and effort, and generating stress.

Together, more than 40 staff members from a dozen different roles and teams agreed on focus areas that would help deliver greater value to customers with less effort and stress, and increased happiness.

A key aspect to understanding the current state was to “go to gemba,” or go to where the work happens. The purpose of doing so was to observe processes and how people experienced the work firsthand. Our practitioners went to Dome’s offices and project sites and conducted interviews with staff and clients to get their perspective on what did and didn’t work in their day-to-day operations. This allowed Dome staff and our practitioners to deeply understand the true nature of the problems rather than speculate. We created videos for training purposes with Dome team members in which they explained how to apply the Lean tools and solutions that were being implemented, which made the solutions relatable and created buy-in to adopt the new way of thinking and working.

In another area of the business, we focused on improving the invoicing process that staff members found cumbersome. After a Haley & Aldrich–facilitated workshop, staff uncovered that the root cause of invoicing challenges was that the team was not collecting the right data during project kickoffs. By establishing better internal processes to ensure the right information was gathered initially, staff wasted less time searching for necessary information and correcting errors.

Haley & Aldrich’s continued Lean efforts have been critical in building our team and shaping our culture. I sincerely believe that how our team navigated challenges brought on by the pandemic proved to be our finest hour, and that is in no small part due to the example set by the Haley & Aldrich team.

Rob Lynch, President & CEO of Dome Construction

After some initial successes in which Lean thinking and behaviors enhanced Dome’s culture and work processes, Dome’s staff began to learn more about Lean behaviors: why problems occur, what clients really want, and finding ways to ultimately deliver even greater value. Now, Dome Construction has established a culture of continuous improvement and respecting its staff and is considered one of the “Best Places to Work” by San Francisco Business Times.

Value delivered

- Created a culture focused on Dome’s most valuable resource, its people, which contributed to their ranking as one of the “Best Places to Work” by San Francisco Business Times

- Developed a culture of identifying customer needs before taking action

- Improved several internal processes resulting in better use of resources

- Improved the efficacy of Dome’s project teams by playing an integral role in evolving Dome’s collaborative planning process for construction projects

As one employee said, “We feel appreciated because Dome gave us opportunity to make things better. They invested in us. We were really busy, and yet it was still possible.”