Government infrastructure

Haley & Aldrich’s innovative PFAS destruction tech offers a solution to DOD’s remediation needs

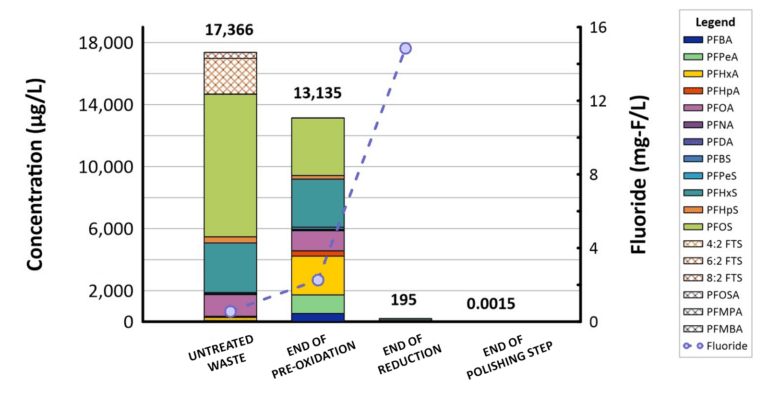

Nearly 100% of PFAS

destroyed by EradiFluor

+15 mg/L concentration of fluoride

measured at the end of the process, demonstrating that PFAS molecules were fully transformed into fluoride, a harmless by-product

Summary

- With public and regulatory pressure mounting, the Department of Defense (DOD) urgently needed innovative technologies to remediate PFAS. Existing technologies concentrated, but did not destroy, PFAS-containing waste.

- The DOD financially supported a Haley & Aldrich team as we worked to develop a new PFAS destruction technology, EradiFluor. After promising tests, we conducted the first field test at a U.S. naval installation on the Eastern Seaboard.

- Coordinating with Navy remediation staff, we treated a concentrated waste containing PFAS (up to 17,366,000 ng/L) from in situ foam fractionation treatment of groundwater impacted by firefighting foam.

- Both field and laboratory analytical data provided multiple lines of evidence demonstrating that EradiFluor can destroy PFAS safely at ambient conditions, at low cost, and with no harmful by-products to levels below the EPA’s stringent requirements.

Client challenge

A U.S. naval installation on the Eastern Seaboard had a challenge shared by many DOD sites: PFAS contamination. Like commercial airports, DOD sites have often relied on PFAS-containing foam to fight fires. Foam runoff can contaminate the surrounding environment with PFAS, which, according to some studies, are associated with human health impacts. The DOD has estimated that it will spend more than $9.7 billion from FY2024 on to clean up this PFAS contamination across its sites.

And with public and regulatory pressure mounting, the DOD urgently needed innovative technologies to remove PFAS from the environment. This group of thousands of chemicals, known as per- and polyfluoroalkyl substances, are notoriously difficult to destroy. Although some treatments existed, they would only concentrate or transfer PFAS to another form that still needed disposal. Sending this treated waste to landfills could be cost-prohibitive, and it only transferred the problem and associated liabilities — landfill leachate is also a known source of environmental PFAS contamination.

To attack its PFAS problem, the DOD financially supported Haley & Aldrich’s research to develop and demonstrate a treatment technology that would effectively destroy PFAS. At this particular Navy site, Haley & Aldrich conducted a field test of our new PFAS destruction technology, EradiFluor.

Our approach

A Haley & Aldrich team had already tested EradiFluor extensively in our lab in Rochester, New York, using concentrated waste from actual sites and achieved near-total destruction of various classes of PFAS. Our team knew the technology had several advantages that would transfer to the field, including:

- Ambient pressure and temperature: The system operates under ambient pressure and temperature as it relies on ultraviolet (UV) light and common chemicals to destroy PFAS.

- Safer to operate: Because this system does not require high temperature and high pressure, special health and safety measures are not needed.

- Lower energy use: The system consumes less energy than comparable destruction technologies because it operates under ambient pressure and temperature.

- Flexible, scalable implementation: Each individual unit has a small footprint and can be combined with other units, depending on the amount of contaminated material.

At the Navy facility, we treated a concentrated waste produced from an in situ foam fractionation system for remediation of groundwater contaminated with PFAS. We initially characterized a sample of the concentrated waste, called foam fractionate. This process detected multiple PFAS chemicals in varying concentrations.

To define success for our field test, we set clear performance objectives for decreases in PFAS concentration, defluorination (the method by which the technology would destroy PFAS molecules), and cost and energy savings. We also wanted to get a qualitative impression of EradiFluor — how easy it would be to operate and control in a field setting, especially for technicians without specialized training.

Coordinating with Navy remediation staff, we successfully treated the foam fractionate waste, collecting samples before, during, and after treatment. Our results at the end of each step showed a consistent reduction of PFAS concentrations.

Above: Results from the field demonstration showing effective destruction of various PFAS. Most precursor compounds were transformed and removed after the pre-oxidation step. After the polishing step, all residual PFAS were undetectable, except one compound, PFOS, which we measured at 1.5 ng/L (below the EPA’s maximum contaminant levels (MCL) of 4 ng/L). Meanwhile, fluoride — the nontoxic final degradation product — increased to 15 mg/L in concentration, demonstrating complete defluorination (or mineralization) of PFAS.

In other words, EradiFluor delivered: The field test showed that it provides a powerful approach as the DOD and the private sector work to resolve one of our most urgent environmental issues.

Value delivered

- Achieved near-complete defluorination and a nearly 100% concentration decrease for 40 PFAS compounds, exceeding our initial criteria for success — all post-treatment concentrations were non-detect except for PFOS, which was measured below the EPA’s MCL for drinking water

- Delivered on a PFAS treatment system that operates economically and reliably under ambient pressure and temperature

- Demonstrated that the system worked smoothly, with close to 100% operation uptime (meaning it worked nearly continuously while deployed)

- Found that EradiFluor takes little specialized training to operate, making it easy to deploy in the field

For more information, contact:

Principal Consultant, Applied Research Leader

Technical Specialist, Environmental Engineer

Principal Consultant