Industrial and manufacturing

Eyeglass manufacturer reduces costs and waste with our help

<30 days

time in which we achieved compliance, avoiding penalties

$10,000s

projected annual savings with our recommended waste treatment process

Summary

- The Washington State Department of Ecology (DOE) reclassified our client’s facility as a Large Quantity Generator of hazardous waste, and gave the client 30 days to correct problems or face penalties and fines.

- Given our expertise with the the state’s programs, the client relied on us to comprehensively meet requirements before the deadline.

- We also looked beyond the state’s concerns and developed a comprehensive dangerous waste management program that helped the facility increase efficiency, improve safety, and reduce costs.

Client challenge

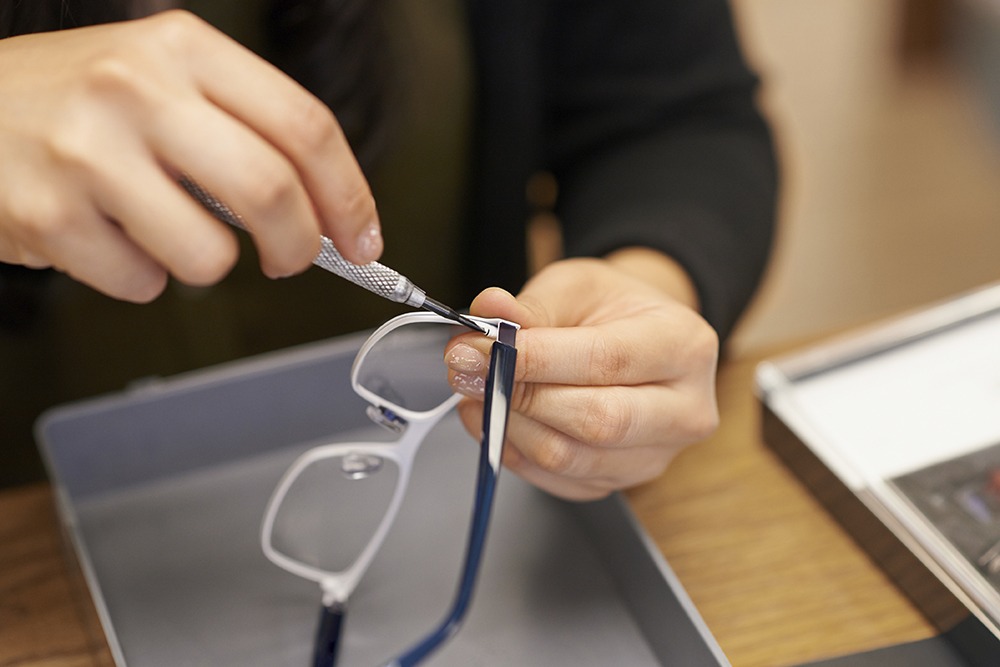

A wholesale eyeglass manufacturing facility was faced with a potential downside to growth when the Washington State DOE reclassified the facility as a Large Quantity Generator of dangerous waste (i.e., hazardous waste) based on its increased production. This reclassification meant the manufacturer was obligated to meet stringent waste management regulations for handling and disposing of these hazardous substances. Following an inspection of the facility, the DOE issued a Notice to Comply (NTC) for several deficiencies in the facility’s dangerous waste management program. The manufacturer was given 30 days to correct the problems or face penalties and fines.

Lacking the in-house knowledge and expertise to reach compliance within such a short time frame, our client turned to Haley & Aldrich for help, given our expertise in hazardous waste management and in-depth knowledge of Washington’s Dangerous Waste Regulations and Dangerous Waste Generator program requirements.

Our approach

With a clear understanding of DOE requirements, our team streamlined the employee training process and bring the facility into compliance in less than 30 days. We prepared all of the required Dangerous Waste Generator program elements and developed a succinct and competent response to the NTC with supporting documentation. What’s more, we looked beyond the DOE’s concerns and developed a comprehensive dangerous waste management program that helped the facility increase efficiency, improve safety, and reduce costs. This program offered the client a way to extend the life of materials through reuse rather than one-use disposal, which reduced waste and saved money.

Value delivered

- Avoided penalties and maintained a positive relationship with regulators by achieving compliance in less than 30 days

- Identified an approach to extend the life of materials through reuse and therefore reduced waste and saved our client money

- Recommended a new waste treatment process that could save the facility tens of thousands of dollars annually in waste disposal and provide a positive return on investment within approximately four months of installation

- Helped engage employees and encourage sustainability by empowering them to proactively address hazardous waste handling and disposal, improving long-term health and safety outcomes

For more information, contact:

Senior Associate